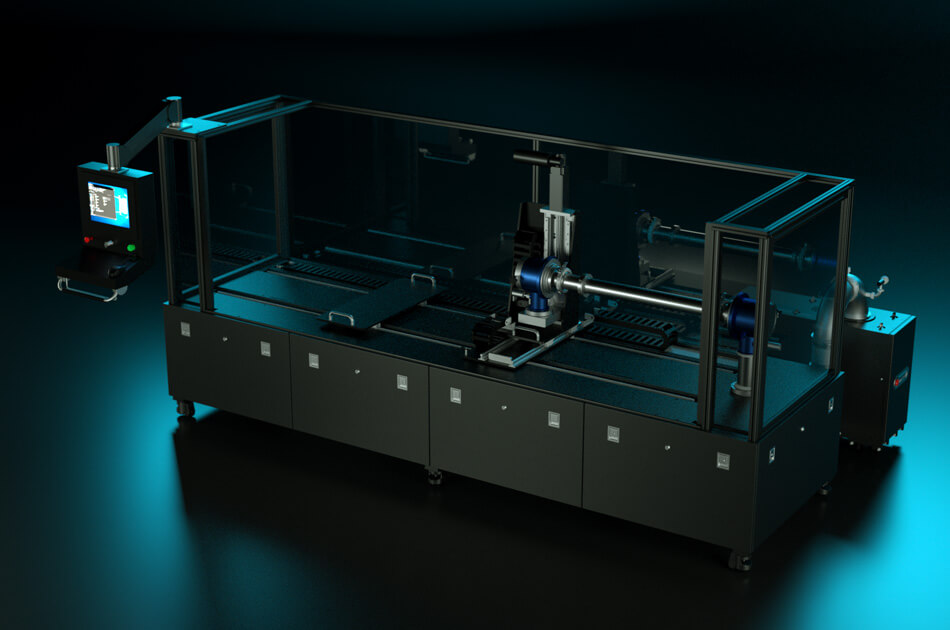

Internal pipe coating is a tricky process, but it’s one that the CS-10 makes simple. This internal pipe coating machine can coat the interior diameters of any number of products and is perfect for industries like oil, gas, and defense.

Do you want to learn more about our internal pipe coating equipment? The team here at ArmorLube is happy to help. Simply contact us with any questions, comments, or concerns, and we’ll do our best to get you the information you’re after. Reach out to our team today for help with the CS-10 or any of our other metal coating equipment.

Length:

Clearance limit 200″ (5080mm)

Width:

Clearance limit 150″ (3810mm)

Height:

Clearance limit 96″ (2439mm)

Footprint:

Actual Machine 158″ (4013mm) Xx 43″ (1092mm) x 82″ (2083mm)

Deposition Rate:

Up to 0.5µm per minute

Max Chamber Size:

Maximum chamber is limited by pulsed power supply

Power Requirements:

208V 100A 3 Phase 5 Wire with Ground (37.5 kVA) Chassis Ground Bar Required

Coating Types:

PECVD, Nitriding etc.

Length:

Clearance limit 200″ (5080mm)

Width:

Clearance limit 150″ (3810mm)

Height:

Clearance limit 96″ (2439mm)

Footprint:

Actual Machine 158″ (4013mm) Xx 43″ (1092mm) x 82″ (2083mm)

Deposition Rate:

Up to 0.5µm per minute

Max Chamber

Size:

Maximum chamber is limited by pulsed power supply

Power Requirements:

208V 100A 3 Phase 5 Wire with Ground (37.5 kVA) Chassis Ground Bar Required

Coating Typess:

PECVD, Nitriding etc.

American Made. Veteran Owned.

© Copyright 2022 ArmorLube LLC. All Rights Reserved.