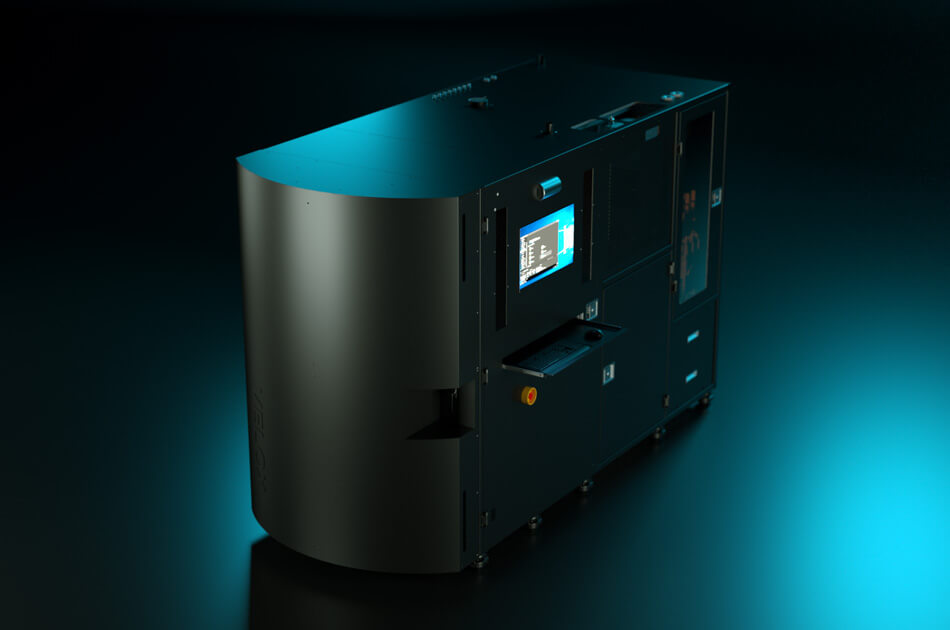

The Velox delivers the fastest plasma nitriding process and rapid cooling solution on the market today. It’s the ideal solution for manufacturers that need rapid cycle times to achieve the greatest cost efficiency.

We all know what it’s like to have equipment that is far too slow at its job. When even one step of your manufacturing process is extended, it can throw off everything else and cause some serious damage to your efficiency. All those worries are erased, though, when you invest in a Velox plasma coating machine. With quick nitriding treatments, you’ll find your metal strengthened in no time.

This is a low-profile machine with quick change capabilities, which allows you to speed up your processes! Curious to learn more about the Velox plasma nitride coating equipment? Just reach out to the team here at ArmorLube—we’re happy to answer your questions.

Length:

Clearance limit 220″ (5580mm)

Width:

Clearance limit 159″ (4039mm)

Height:

Clearance limit 96″ (2439mm)

Footprint:

Actual Machine 124″ (3150mm) x 52″ (1321mm) x 88″ (2235mm)

Deposition Rate:

Up to 0.5µm per minute

Max Chamber Size:

10″ Process Zone 10″ (254mm) x 36″ (914.4mm) • 12″ Process Zone 12″ (304.8mm) x 40″ (1016mm)

Power Requirements:

208V 100A 3 Phase 5 Wire with Ground (37.5 kVA) Chassis Ground Bar Required

Coating Types:

PECVD, Nitriding etc.

Length:

Clearance limit 220″ (5580mm)

Width:

Clearance limit 159″ (4039mm)

Height:

Clearance limit 96″ (2439mm)

Footprint:

Actual Machine 124″ (3150mm) x 52″ (1321mm) x 88″ (2235mm)

Deposition Rate:

Up to 0.5µm per minute

Max Chamber

Size:

10″ Process Zone 10″ (254mm) x 36″ (914.4mm) • 12″ Process Zone 12″ (304.8mm) x 40″ (1016mm)

Power Requirements:

208V 100A 3 Phase 5 Wire with Ground (37.5 kVA) Chassis Ground Bar Required

Coating Typess:

PECVD, Nitriding etc.

American Made. Veteran Owned.

© Copyright 2022 ArmorLube LLC. All Rights Reserved.