Vacuum coating technology has revolutionized many products, from electronics to automobile parts. But what has made this technology so innovative that it has impacted every industry, down to the medical field? Through this blog, you will learn the great influence of vacuum technology and how the coating branch has developed over the ages. Let’s get our notepads and pens ready to learn the history of vacuum coating technology.

What Is Vacuum Coating Technology?

In a nutshell, vacuum coating also goes by the name of thin-film deposition. Moreover, this technology uses a vacuum chamber to apply a paper-thin layer of coating onto a substrate’s surface. The coating prevents the object’s ground from wearing down.

Why Do We Use a Vacuum While Doing Coatings?

Vacuum technology does two things to ensure the coating process is successful. When a vacuum is inserted into the chamber, it provides a straight path for atoms to arrive without scattering so they can adhere to the material without struggle. It also cleans the surface before the particles enter the space, so there is no unstable layer when attempting to stick.

The History of Vacuum Coating Technology Before 1800

Why do we use vacuums the way we do these days? It all came from the great minds of scientists and other significant influences at the birth of vacuum coating technology. Let’s go through the time vacuum and explore what Descartes and Galileo did to develop and inspire advancements in this innovative technology.

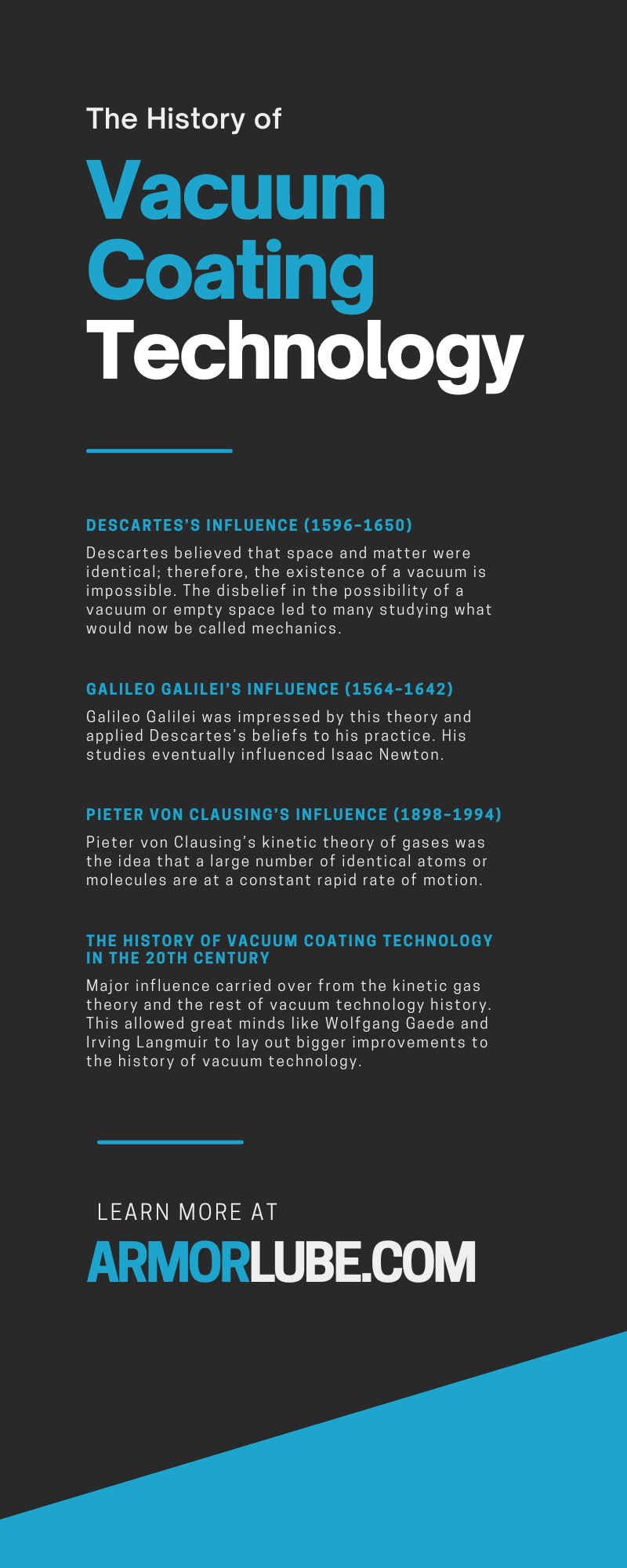

Descartes’s Influence (1596–1650)

Descartes believed that space and matter were identical; therefore, the existence of a vacuum is impossible. The disbelief in the possibility of a vacuum or empty space led to many studying what would now be called mechanics. Specifically, people studied the mechanics of how one existential plane could exist while another didn’t.

Galileo Galilei’s Influence (1564–1642)

Galileo Galilei was impressed by this theory and applied Descartes’s beliefs to his practice. His studies eventually influenced Isaac Newton. Later, it was proved that air has weight and density; therefore, air would be considered a substance since it holds weight.

The History of Vacuum Coating Technology After 1800

The great influences of Descartes, Galileo, and many others have further developed vacuum technology through the 1800s and beyond. Here is the timeline of Pieter von Clausing’s influence on vacuum coating technology.

Pieter von Clausing’s Influence (1898–1994)

Pieter von Clausing’s kinetic theory of gases was the idea that a large number of identical atoms or molecules are at a constant rapid rate of motion. This theory heavily influenced the lamp industry. The theory von Clausing and other partners developed also assisted in creating the gauge, which was considered a measure of a physical quantity at the time.

The History of Vacuum Coating Technology in the 20th Century

Major influence carried over from the kinetic gas theory and the rest of vacuum technology history. This allowed great minds like Wolfgang Gaede and Irving Langmuir to lay out bigger improvements to the history of vacuum technology.

Wolfgang Gaede (1878–1945) invented the mercury pump, which used the chloralkali electrolysis process to transfer mercury into a chamber that crosses over the bottom of an electrolysis cell. Sometime after the invention of the mercury pump, Irving Langmuir (1881–1957) worked on incandescent pumps with gas.

The gas ignited light onto an incandescent filament—this process happens when nitrogen gas is placed inside a bulb and twisted in the filament to create tungsten vaporization. This is how the Nernst lamp came to fruition—though it is obsolete, the design is still used today.

The Highlights of Vacuum Coating Technology

There is so much history to learn about vacuum coating technology, so we had to summarize the highlights from the development of this technology. This is just one thorn of the vacuum technology branch.

Thin Film

Thin film and sputtering were the first two types of vacuum coating technology. However, thin film came after sputtering—W. R. Grove was the first to record the phenomenon of thin films forming in a vacuum.

Where did thin film come from? In a nutshell, the thin film comes from the deposition vapor phase. It’s believed that this first happened when a ceramic pot was accidentally filled with metal layer deposits near a charcoal fire specifically used to break down metal ores.

Sputtering

The first vacuum coating process was sputtering, or sputter deposition. This process uses high inductive voltage that slowly removes the targeted surface, so it’s used to coat the bottom or top of the targeted area.

Atomic Layer Deposition (ALD)

Atomic layer deposition (ALD) is a coating used primarily in the medical industry for surfaces with hard-to-reach areas. The deposition profile, its chemistry and thickness, can be altered for better adhesion to the material.

Cathodic Arc

The cathodic arc uses electrical pulses to remove material; the target surface’s broken molecules are regenerated through the vacuum chamber and coated on the material.

PVD

PVD is the most common type of vacuum coating technique. Once placed into a chamber, vapor evaporates the object’s surface, flushing it back through the vacuum and recoating the target area. Swilling the evaporated contents of the material’s surface doesn’t act as a replacement layer like a fresh coat of paint. What it does is something different. The removed remnants of an object’s surface are, in a way, recycled by being removed and coated through the vacuum, then reapplied with the vapor.

How Vacuum Coatings Are Used in the Professional World

Because of so much technological advancement, the professional world has gotten busy utilizing vacuum coating techniques to enhance workspaces, including equipment.

Manufacturing Industry

Manufacturing has improved in many ways, such as implementing 3D printing and vacuum coating processes like ALD and PVD. These processes have made machine parts more compliant and stronger to use.

Medical Field

The medical field is another area that utilizes vacuum coating processes to the fullest by using black titanium nitride in their PVD coating formula. Titanium reduces the risk of causing adverse reactions like nickel, so medical tools use titanium PVD coatings instead.

Aerospace Industry

Aerospace utilizes coating processes as much as the medical and manufacturing industries. For example, if an aerospace engineer expects a part to be able to survive while in the air, they need to follow better strategies. This includes vacuum coating, which uses properties that protect vulnerable aircraft parts from heat, harsh environments, and friction.

Be Part of Vacuum Coating Technology History With ArmorLube

If the vacuum coating technology history sounds compelling, why not become part of its history by utilizing the practices? ArmorLube is a leading provider of vacuum coating equipment that can enhance your tech and improve the work environment.

Come and find out what a vacuum coating machine can do to improve your business’s production line. Our machines are great for every industry, including yours! Let’s get to talking and find the best vacuum coating process for your business.