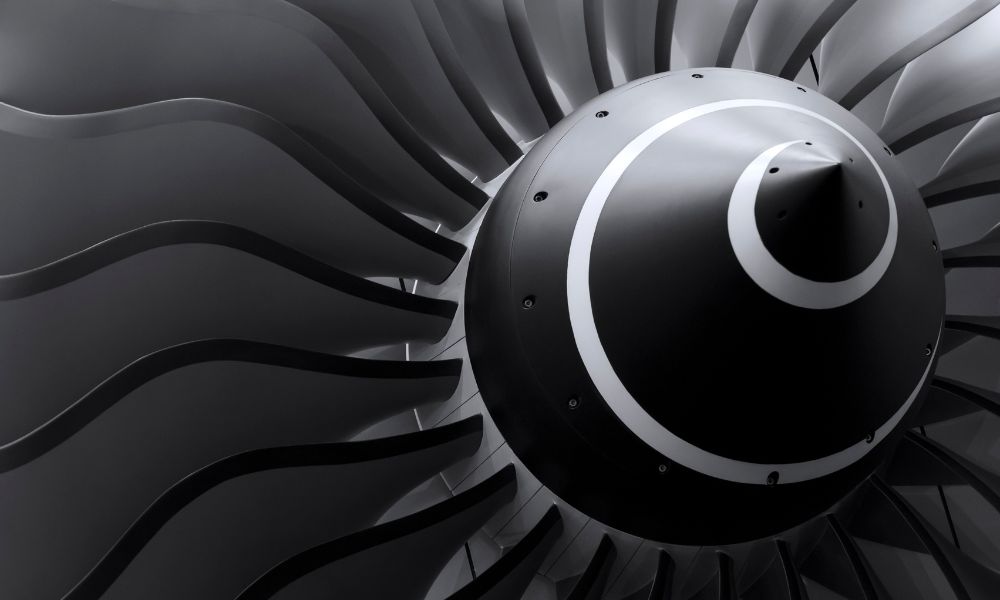

Every flying object deserves a special coating to protect against extreme temperatures, corrosion, and hazardous gases. While the coatings help heighten defense in the aerospace industry, you need to know the importance of the material and why the aerospace industry uses it.

Why Is a Coating Necessary for Aerospace & Defense?

A coating is necessary for any situation where a plane, spaceship, or other aircraft needs paint for protection from corrosion and extreme temperatures. Buying a high-grade paint finish is good if you want the airplane, helicopter, or jet to work the best in any climate.

Perhaps it’s not the protection that pulls you in but the exterior’s appearance upon applying and drying the paint. Paint finisher colors are distinct and add a touch of individuality to the aircraft. Overall, a unique appearance and eco-friendly ingredients are what you want most from your coating.

Prevents Corrosion

Many industries dealing with metal parts have experienced corrosion at least once or twice. Corrosion isn’t reversible, so it’s best to apply a coating right away to prevent any corrosive buildup in the future. Often, metals like aluminum lose their durability when they accumulate rust.

Corrosion brings many problems, including pitting in humid locations with bodies of saltwater nearby. A high-quality finisher can save even the most vulnerable metal parts on your aircraft.

Protects Sensitive Metals

As mentioned previously, coatings prevent corrosion and add security to other sensitive metals, especially ones unsuitable for certain climates, like copper. Corrosion doubles when exposed to higher temperatures. It damages equipment and furthers the need for maintenance.

A finisher reduces the potential for corrosion and protects metals. Alloys like titanium need a special coating to protect against abrasion and seizing. Another type, magnesium, needs a finisher low in COF count, resulting in better protection from wear and reducing the chance of outgassing.

Survives in Every Temperature

Temperatures are a serious issue in metal industries, but they don’t need to be an ongoing concern if you have the right paint finisher. Whether it’s incredibly cold or hot, the finisher holds its strength against temperatures, from dangerously low negatives to alarmingly high heat.

Prevents Gases From Escaping

Outgassing is the release of gases from their present form; whether trapped or frozen, the gases escape once the barriers break down. If parts of an aircraft have toxic gases or alloys, they need a protective sealant across the metal so the gas and alloys don’t escape.

Our industrial coating machines are compatible with every aircraft to enhance defense. Now that you know the importance of coatings in aerospace and defense, you can create a list of vulnerable areas of your aircraft and how you’d like to keep them protected.

Expand your defense with ArmorLube. We’re a respected name in the aerospace industry that looks to enhance every company’s aircraft. Contact us to learn more about our coating systems for your aircraft.