Just as superheroes use their unique powers to protect and improve the world, diamond-like carbon (DLC) coating is a crusader in the automotive industry. Much like our comic book heroes, this high-performance coating silently works behind the scenes, making a massive impact on industries. DLC safeguards engine parts, transmission and suspension components, brake systems, and more, effectively reducing maintenance costs, improving fuel efficiency, and contributing to environmental sustainability. DLC coating is the unsung hero of the automotive world, tirelessly working to drive the industry forward, one component at a time.

In our quest to explore the superhero of the automotive industry, we unveil which automotive components benefit from DLC coating. From engines to brakes, let’s discover how this silent hero works its magic.

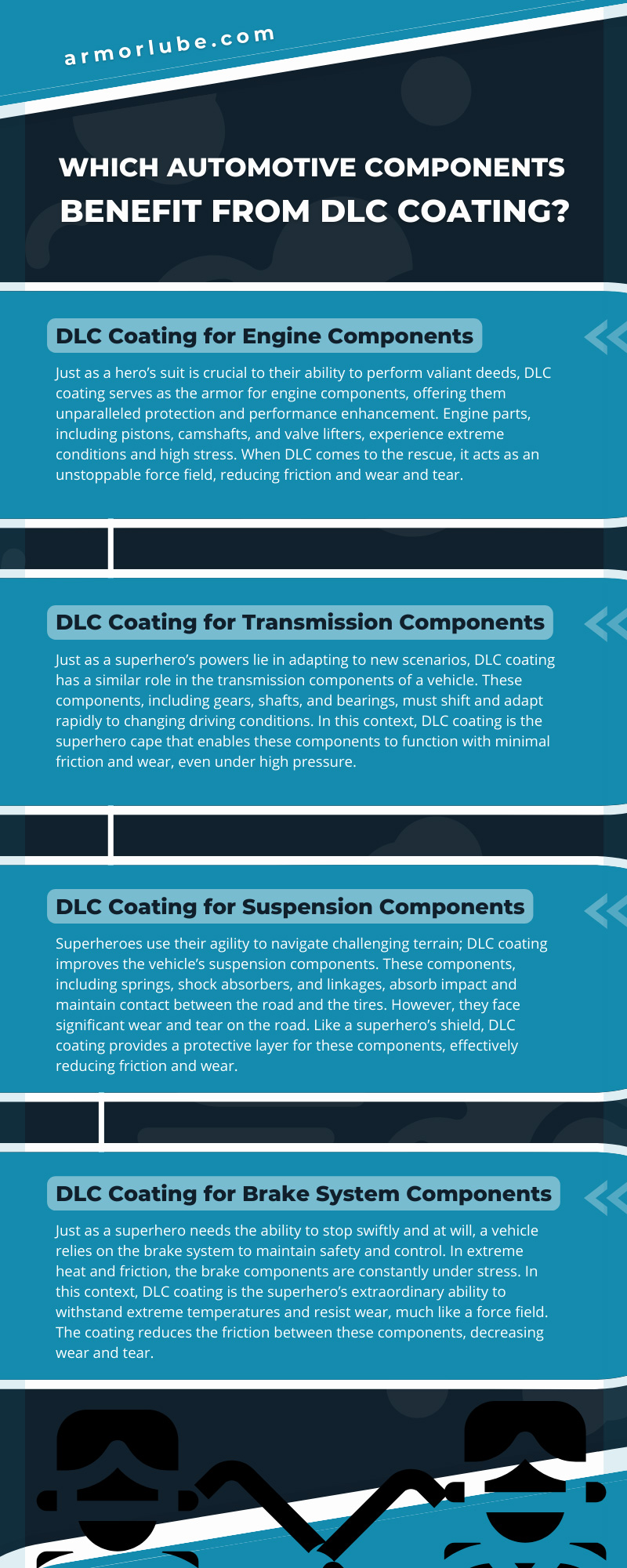

DLC Coating for Engine Components

Just as a hero’s suit is crucial to their ability to perform valiant deeds, DLC coating serves as the armor for engine components, offering them unparalleled protection and performance enhancement. Engine parts, including pistons, camshafts, and valve lifters, experience extreme conditions and high stress. When DLC comes to the rescue, it acts as an unstoppable force field, reducing friction and wear and tear. This protection results in a significant enhancement in the component’s performance and longevity. Like a superhero, DLC-coated engine parts perform at optimum levels, even under the most challenging conditions, making it a true hero in engine technology.

DLC Coating for Transmission Components

Just as a superhero’s powers lie in adapting to new scenarios, DLC coating has a similar role in the transmission components of a vehicle. These components, including gears, shafts, and bearings, must shift and adapt rapidly to changing driving conditions. In this context, DLC coating is the superhero cape that enables these components to function with minimal friction and wear, even under high pressure. DLC coating extends transmission parts’ lives by reducing replacement frequency and associated costs. So, this coating’s resistance and durability ensure the transmission system continues optimally, adapting to every twist and turn on the road.

DLC Coating for Suspension Components

Superheroes use their agility to navigate challenging terrain; DLC coating improves the vehicle’s suspension components. These components, including springs, shock absorbers, and linkages, absorb impact and maintain contact between the road and the tires. However, they face significant wear and tear on the road. Like a superhero’s shield, DLC coating provides a protective layer for these components, effectively reducing friction and wear. As a result, the suspension components’ lifespans extend, improving ride quality and comfort. DLC coating is a powerful ally in maintaining the integrity and performance of suspension components through its extraordinary ability to resist wear.

DLC Coating for Brake System Components

Just as a superhero needs the ability to stop swiftly and at will, a vehicle relies on the brake system to maintain safety and control. In extreme heat and friction, the brake components are constantly under stress. In this context, DLC coating is the superhero’s extraordinary ability to withstand extreme temperatures and resist wear, much like a force field. The coating reduces the friction between these components, decreasing wear and tear. The layers extend the brake system’s lifespan and efficiency, providing a safer and smoother driving experience. DLC coating is the superhero power that gives the brake system resilience and robustness, ensuring reliable performance even under demanding circumstances.

Coating in Performance Enhancement

Just as a superhero’s unique powers enhance their abilities, DLC coating boosts the performance of automotive components. The coating’s remarkable properties, including its high hardness, low friction coefficient, and excellent adhesion, make it ideal for improving automotive part performance. By significantly reducing friction, DLC coating allows engine and transmission components to operate better, benefitting the vehicle’s overall performance.

Moreover, the coating’s ability to withstand extreme heat and pressure ensures that components perform optimally under stress. Much like a superhero, DLC coating empowers automotive components, helping them achieve their full potential and deliver superior performance.

DLC Coating for Fuel Efficiency Improvement

Just as a superhero’s efficiency proves their power, a vehicle’s fuel efficiency is also indicative of its performance. DLC coating improves a vehicle’s fuel efficiency by reducing friction in various engine and transmission system parts, decreasing overall energy consumption. As a result, more of the energy from the fuel can contribute to momentum, leading to considerable improvements in fuel efficiency. Like a superhero’s ability to do more with less, DLC coating improves fuel economy in a vehicle by using less energy.

The Contribution of DLC Coating to Component Longevity

A superhero’s strength enables them to endure longer, just as DLC coating extends the life of automotive components. This remarkable coating forms a hard, wear-resistant surface that protects the underlying material from stressor damage. This defense mechanism significantly reduces damage rates, which prolongs an automotive component’s lifespan.

DLC coating is like a superhero’s endurance power, ensuring that automotive components can continue to perform effectively and reliably for longer. This factor adds value to the vehicle and minimizes the need for frequent replacements, leading to significant future cost savings.

DLC Coating for Reducing Maintenance Costs

Like a superhero providing security, DLC coating significantly reduces maintenance costs for automotive components. This protective coating extends its lifespan, decreases susceptibility to wear and tear, and strengthens critical parts like engines, transmissions, suspensions, and brakes. DLC coating reduces overall maintenance costs by lowering the need for repairs and replacements, making it a valuable ally for cost efficiency in the automotive industry.

DLC coating is beneficial for various vehicle components. Akin to a crusader, DLC works around the clock to protect and enhance all essential parts for better performance and efficiency. Car manufacturers can witness significant maintenance cost reductions and fuel efficiency improvements thanks to the remarkable properties of DLC coating.

Armorlube, the ultimate provider of DLC coating equipment in the industry, stands ready to transform your ride with the necessary equipment. Are you ready to embrace the power of Armorlube and equip your automotive components with this superhero-level protection and performance enhancement? Contact us to learn more about how DLC is a superhero in your industry.